Save Lives! Integrate Wearable Health Monitors into Automobiles

Wearable systems that monitor health through vital signs have grabbed the attention of the healthcare, technology

and consumer sectors over the last decade. Motivated by rapidly increasing healthcare costs and propelled by recent

technological advances in ultra-small sensors, low power computation, power sourcing and wireless communication, the

continued advance of wearable, sensor-based systems will transform the future of healthcare. By enabling proactive

personal health management and continuous monitoring of health conditions, healthcare professionals can predetermine

needed care for their patients.¹ Wearable health monitoring systems are becoming one of the fastest growing

consumer markets worldwide.

Hundreds of companies around the world are diligently working to create new wearable health monitoring devices. The

competition is immense, and companies are constantly looking for ways to gain an edge. Designers face many tough

challenges including power consumption, ergonomics, accuracy, RF integration, cost and more.

The most challenging design requirements for wearable devices are size, ergonomics, power consumption and health

monitoring accuracy. This is especially critical in applications where an individual’s health must be monitored

continuously over long periods of time. These wearable devices need to be comfortable, stylish and last at least an

entire day before a recharge is needed. These factors have a direct impact on the product’s real utility.

As wearable health monitoring devices become more widely used in medical platforms rather than just as fitness

monitoring systems, the "on time" or "usable time" before battery recharge becomes much more important. Fitness

users typically only wear the device for short periods of time while exercising. For health monitoring, wearable

devices must be active and usable for very long periods of time. Battery life between charges is one of the most

important criteria for a wearable health monitoring device.

The challenge for power consumption and battery life is balancing battery capacity and size with efficient power

management (i.e. low power modes, efficient designs, etc.).4 A primary method to increase battery life is

to increase the system’s power efficiency. Various load circuits within the system (such as the microcontroller,

radio, sensors, and analog front-ends) must be driven from voltages different from the battery voltage – thus, each

one requires a dedicated DC/DC converter, which brings with it associated losses.

Until recently, the primary focus for voltage regulation DC/DC converters has been the efficiency of power delivery

in active mode, from light to peak to full load. With the power efficiency well understood, and improvement reaching

saturation, the focus is now shifting to improving power savings in passive mode. This shift is demanded by the

popularity of new gadgets that spend a lot of time in a passive state, with only infrequent spurs of activity. It is

clear that if idle and sleep mode are the dominant operational modes, this is where the power savings must come

from.5

For example, a system powered by a 40mAh, 1.55V silver oxide coin cell battery will have a shelf life of one year

before the battery runs out of charge, assuming the current drawn is about 4µA. A current reduction of a single

microamp would then increase the wearable shelf life by approximately three months! With this in mind, looking at a

traditional product portfolio of conventional low power ICs for mobile and hand held devices, which consume tens of

microamps of quiescent current and several microamperes of shut-down current, it’s easy to see that any improvement

in these parasitic currents will be beneficial.5

Companies such as Maxim Integrated are striving to meet these challenges with ICs designed specifically for the

wearable market. The emphasis has been on making ICs smaller in physical size while operating at ultra-low power

levels. As an example, the MAX1722 boost

converter is optimized for low power consumption applications. This device uses aggressive power savings techniques

to reduce current consumption when the system is in sleep mode and the regulator is shutdown. Shutdown currents can

still be costly, so when the MAX1722 is in

shutdown, all the regulator control circuits are switched off, leaving only the unavoidable parasitic

leakages.5

Smart watches and wearable healthcare systems incorporate many "pivot" type ICs, such as biosensors, wireless

transceivers, and microprocessors. The focus on power consumption and savings should not be limited to these parts

within the system, but must include the supporting ICs, as well. Many other ultra-small, low power devices support

the main infrastructure of a wearable device including supervisors, data converters, and RF chips. Maxim offers a

wide selection of such ICs developed with the wearable market in mind.

A variety of system prototypes and commercial products have been produced in recent years which provide real-time

health feedback directly to the user or to a medical center or physician. These systems can alert the individual or

professional in case of imminent, health threatening conditions. Maxim has developed several healthcare reference

designs to help customers quickly get started building, testing and evaluating their own systems. These complete

designs include full schematics, bills of materials (BOM), PCB Gerber files and support software. One design of note

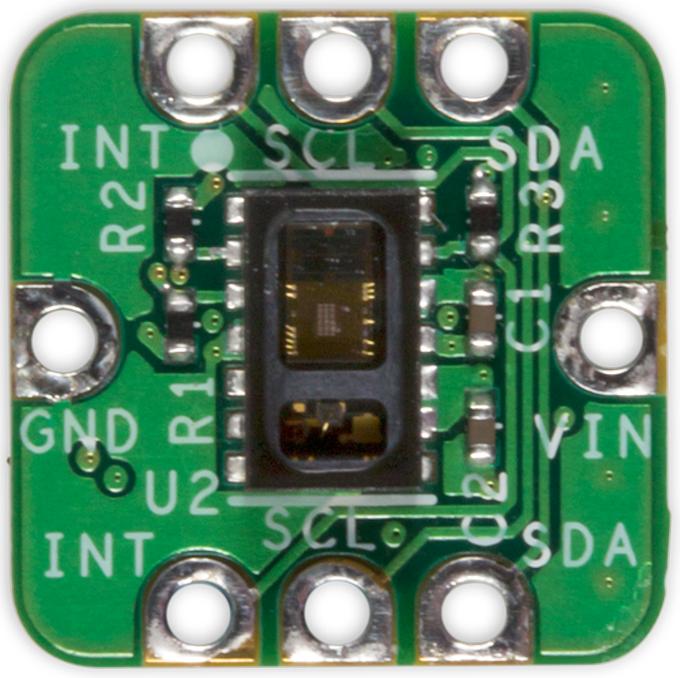

is the MAXREFDES117, Heart Rate and Pulse Oximetry Monitor

(Figure 1). This low power, optical heart rate module integrates red LEDs, IR LEDs, and a power supply. The tiny

board is optimized for wearable applications and may be placed on a finger or earlobe to accurately detect heart

rate. The versatile module works with Arduino® and mbed® platforms for quick testing,

development and system integration. A basic, open-source, heart rate and SpO2 algorithm is included in the example

firmware.

Figure 1: MAXREFDES117

PCB Board

The MAXREFDES117 utilizes a heart-rate/SpO2 sensor

(MAX30102), an efficient, low power step-down converter (MAX1921), and an accurate level translator with I²C

capability (MAX14595). The entire design typically operates at less than 5.5mW when using with the example firmware.

A block diagram of the system is shown in Figure 2.

Figure 2: The MAXREFDES67# reference design block diagram.

Moving forward, how can we use the latest technology in wearable devices while also helping society and possibly

saving people’s lives? The automotive industry is highly motivated in this area. Automobile designers are

enthusiastically adding more electronics into all aspects of automobiles for comfort, efficiency and safety. This

technology has the potential to reduce the likelihood of automobile fatalities by alerting emergency responders to

victims’ vital signs in the event of an accident or medical emergency.

Consider these statistics on driving and traffic related deaths and injuries:

- According to the U.S. National Safety Council, 38,300 people were killed and 4.4 million injured on U.S. roads

in 2015. From January to June 2016, the United States was on track to have its deadliest traffic year since 2007,

with nearly 19,000 people killed as a result of motor vehicle accidents.

- - Nearly 2.3 million "serious injuries," defined as those requiring medical assistance, were sustained during

the same six-month period, up 30 percent when compared with the first half of 2014. In a similar upward trend, the

estimated costs of these crashes—including medical expenses, wage and productivity losses and property

damage—increased 24 percent, to roughly $152 billion.²

The main emphasis until now for wearable health care devices has been in the fitness market, to monitor health

while exercising – such as while biking, running or similar activities. Wearable systems include a variety of

miniature biosensors capable of measuring significant physiological parameters, such as heart rate, blood pressure,

body and skin temperature, oxygen saturation, respiration rate, and electrocardiogram. The measurements obtained are

communicated via a wireless or wired link to a central node (for example, to a personal digital assistant device or

a microcontroller board). The information can then be displayed on a user interface, or the aggregated vital signs

can be transmitted to a medical center.

Automobiles have the ability to act as the central node to deliver this information to health care providers,

emergency responders, or police as needed. Traffic related deaths and injury statistics can be greatly reduced by

implementing current technology into motor vehicles of the future. Through the use of a simple wearable health

monitoring system in conjunction with current alert systems such as OnStar® or Life

Alert®, a person’s vital signs, including heart rate, temperature and blood pressure, could be sent

to a doctor or emergency responder. This would save critical time by allowing them to prepare for or administer

proper care as soon as possible. To accomplish this, everyone within a vehicle would need to sync their wearable

device to the automobile’s on-board alert system. This could happen once the person is within a reasonable vicinity

of the vehicle so that in the case of an ejection the link would remain. For family vehicles, the wearable device

worn by each person in the car would automatically connect every time the device is near the vehicle. Once connected

to the vehicle, the vital signs would be displayed on the on- board screen and also sent directly to the alert

staff, in the case of a catastrophic event. With this system a parent would have the security of knowing that in

such an event, their child’s health status would be available to medical professionals immediately.

Conclusion

For engineering firms and technology companies, the time is now to not only participate in the wearables movement,

but to also lead it by enabling new solutions to promote healthier lifestyles, prevent injuries, and ultimately,

save lives. Maxim Integrated has been working closely with consumer wearable companies in this regard and is well on

the way toward meeting the tough design challenges posed. By integrating sensors, further miniaturizing components,

and developing new wearable designs and technology, Maxim is actively demonstrating a dedication to the wearable

healthcare industry.

References

- A Survey on Wearable Sensor-Based Systems for Health Monitoring and Prognosis

Alexandros Pantelopoulos and Nikolaos G. Bourbakis, Fellow, IEEE

- U.S. Traffic Deaths Injuries and Related Cost up in 2015

BY Stav Ziv; Newsweek; on 8/17/15 at 2:40 PM

- Design Challenges for Wearables

ECN, Wed, 01/07/2015 - 1:36pmby Karen Lightman, Executive Director, MEMS Industry Group

- 5 Challenges in Wearable Product Design You Can’t Afford to Forget

Design News, 5/06/2015, Mitch Maiman, Intelligent Product Solutions

- Correct Voltage Regulator Selection is Key to Battery Life in Wearables

EDN Europe, 6/16/2016, Nazzareno Rossetti and Meng He, Maxim Integrated